Technically, the answer

to covering most complex convex or concave panels:

After placing 3M Fine Line tape (1/8th, 1/4, to 1/2 inch width)

around the perimeter of individual panel, use the narrow edge

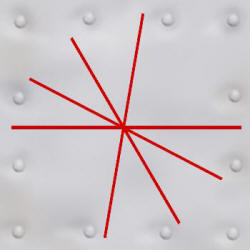

of a straight edge placed upon the surface of the individual

panel. Rotate straight edge from the highest or lowest

point in the compound panel shape. This serves to identify

the largest contact patch and the % of the panel the patch

represents. The largest contact patch area and shape

is rarely parallel to any panel edge. (Re-read that paragraph)

After cutting a piece of Flite-Metal slightly larger than

perimeter of the panel taped to the airframe, peel off the backing

and place the aluminum down onto the surface as parallel to the

taped perimeter as possible.

Before you proceed to use your index finger to lightly press from

the panel center outward to the perimeter, locate the compound

curve contact patch direction and area. Initially apply

Flite-Metal from the straight line representing the center of

the contact patch...using your index finger. As you move from this

straight line contact patch press evenly in all directions as

you move outward burnishing the Flite-Metal proportionally

as you proceed.

Slowly work stretch to perimeter of panel where it

will be burnished against the hard edge of the 3M Fine Line tape. Cut along

hard edge of 3M Fine Line tape with hobby knife and pull

up waste aluminum and tape before final burnish of panel perimeter.

Some false assumptions about panels on "familiar

aircraft":

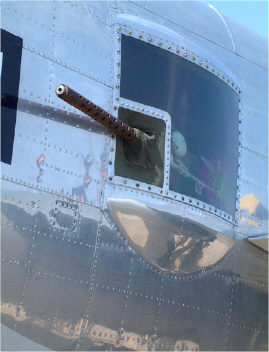

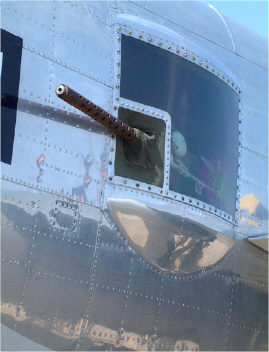

Most aircraft during the first three years of WWII incorporated

overlapped panels, and balance of the aircraft in WWII

incorporated combinations of overlapped and flush, or butt seam

panels.

B-25's

|